Soft Materials Processing

The Walker group has been solving problems involving rheological phenomena of complex fluids since 1997; the group moved west from Carnegie Mellon to Minnesota in 2023. We work closely with other groups at UMN, at other Universities, in National Labs, and elsewhere to tackle problems in soft materials processing.

Research in the Walker group tackles a series of specific issues in the broader problem of the processing of soft materials. Soft materials are those held together by weak ~O(kT) forces and usually present as fluid or gel-like. This includes biological systems, consumer products, food products, processing fluids, and pharmaceutical formulations; in fact, processing of most materials involves a fluid phase that must be fully understood to optimize a process and ensure success. Within this class of materials, the nm -> micron structures that control macroscopic behavior need to be controlled and manipulated. The weak forces that lead to these materials being soft are the same ones that allow for facile manipulation via external forces, meaning that these materials are processible; the structure can continually be altered and changed in response to a processing field or stimuli. The field of polymer processing has led the way on using external fields to control structure and function; the expansion to include soft materials containing self-assembling molecules and colloidal particles is a frontier that will take materials science and engineering into its next era. There is no group of trained scientists more ready to tackle these problems than chemical & materials engineers, especially those trained in colloid and polymer sciences.

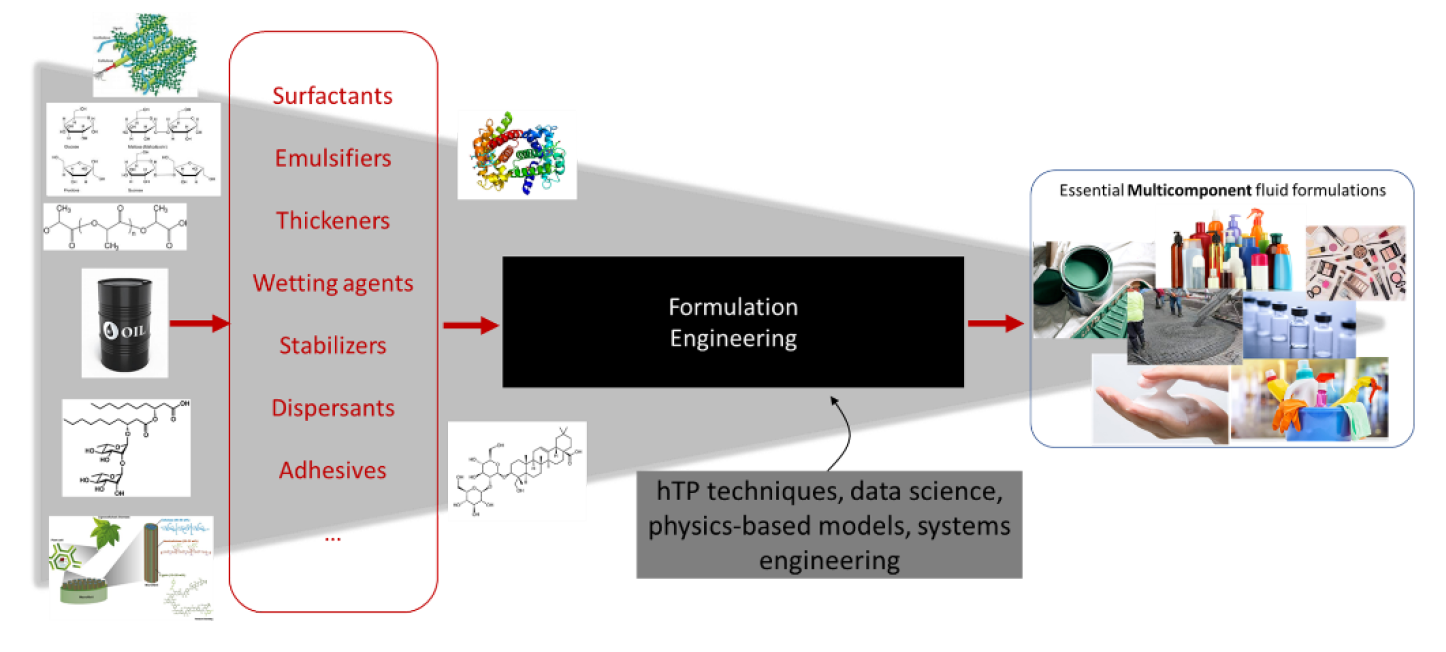

Future focus will be working with a wide range of engineers to develop systematic tools to replace the “black box” of Formulation Engineering, specifically for fluid systems containing macromolecules. This will require chemists and engineers with domain expertise, the development of higher throughput techniques appropriate for macromolecules, and physics-based model development and data science techniques within an optimization framework. A systematic approach will allow for the incorporation and use of more sustainable molecules and polymers.